On June 14, the 10th China (Shanghai) International Technology Fair (referred to as the “CSITF”), jointly hosted by the Ministry of Commerce of the People’s Republic of China, Ministry of Science and Technology of the People’s Republic of China, China National Intellectual Property Administration and Shanghai Municipal People’s Government, successfully concluded.

The core concept of CSITF is “Technology Makes Life More Wonderful,” and its theme is “Innovation-Driven Development, Intellectual Property Protection, and Promotion of Technology Trade.” The fair aims to create an authoritative platform for showcasing, exchanging, and serving to promote the development of technology trade and the implementation of innovation upgrade strategies by integrating domestic and international technological forces and innovative achievements.

CSITF is the only international and comprehensive exhibition in the field of technology trade in China. Since its inception in 2013, it has been held ten times, attracting over 8,500 domestic and foreign exhibitors and more than 390,000 visitors. The fair has hosted over 440 conferences and 300 launch events, becoming an important exhibition, cooperation, and promotion platform for technology trade in China and Shanghai’s technological innovation achievements. As a "loyal partner" of CSITF, Zhejiang organizes enterprises to participate in each session.

Zhejiang places a high emphasis on technology trade and has built a sustainable technological innovation ecosystem. By 2023, the province had 365,000 valid invention patents, with 55.5 valid invention patents per 10,000 people, both leading the nation. In 2023, the province's service trade and technology trade imports and exports reached 598 billion yuan and 33.1 billion yuan respectively, increasing 30 times and 12 times compared to 20 years ago.

Zhejiang Dron Technology was selected as one of the enterprise representatives by the Zhejiang Provincial Department of Commerce to participate in this CSITF!

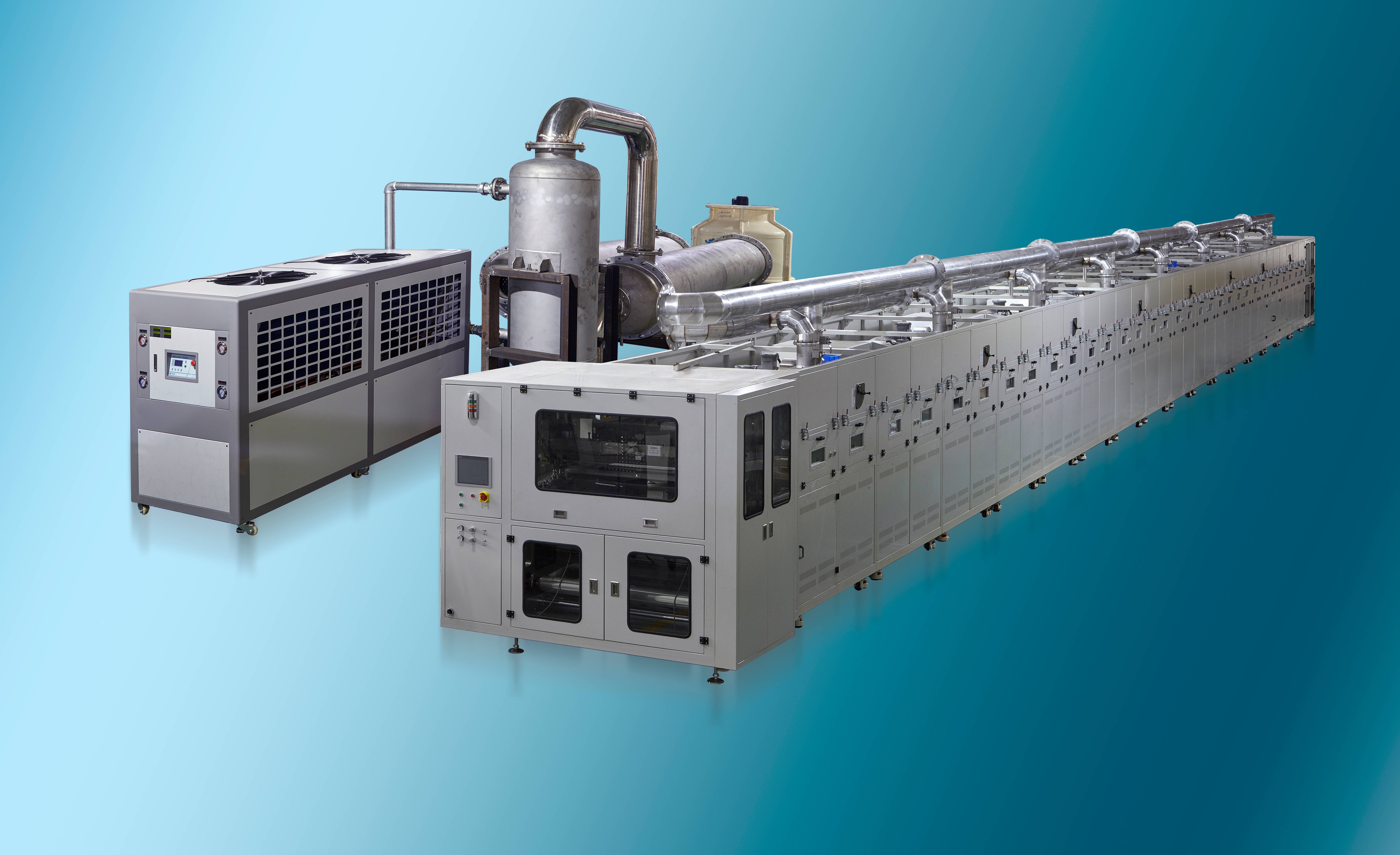

At this year’s CSITF, Zhejiang Dron Technology showcased its outstanding strength and innovative capabilities in the field of casting machine equipment manufacturing, attracting the attention of many domestic and foreign attendees. With its innovative product, the 32SE1200 Casting Machine (with Solvent Recovery), Dron Technology successfully won the "Outstanding Digital Technology Project Award." This award is a high recognition of our technological innovation and product development.

The DL-LYJ-32SE1200 thin-film casting machine is our most advanced product, suitable for the highest production requirements. The advanced servo knife adjustment, servo tension, fast correction, and high-efficiency drying system make it ideal for producing perfluorinated/non-fluorinated ion membranes, proton exchange membranes, and other separators used in flow batteries.

Solvent Recovery Device of the Casting Machine:

Solvent Recovery Device of the Casting Machine:

1. It recycles the organic gases emitted from the casting machine and partially returns them to the air inlet of the casting machine, achieving zero environmental emissions and forming a closed-loop treatment.

2. The entire system is equipped with gas concentration detection alarms, safety explosion-proof design, and concentration exhaust valves.

3. It is designed to monitor and record in real-time the concentration, temperature, and other data for each segment.

Equipment Purpose: This equipment is used to dry the prepared slurry into the desired film. The equipment mainly consists of a vacuum defoaming tank, feeding tank, casting head, drying oven, film correction, film slitting and peeling, and winding sections. The structural design of the equipment is reasonable, effectively controlling the thickness, density, dryness, and uniformity of the green tape, ensuring safety, reliability, high precision, and high efficiency. The safe and reliable ventilation and alarm devices protect the health of operators.

Zhejiang Dron Technology Co., Ltd., established in 2004, is a high-tech enterprise integrating development, design, production, and sales services. We specialize in supplying complete line production equipment for alumina ceramic substrates, aluminum nitride ceramic substrates, silicon nitride ceramic substrates, LTCC, MLCC, HTCC, LCCC, SOFC (solid oxide fuel cells), flexible magnetic material films, proton membranes, ion membranes, polymer films, pharmaceutical filter membranes, metal films, food glue films, etc. Our products include fully automatic large-scale equipment and experimental R&D specialized equipment, such as roller benches, vacuum defoaming tank, experimental casting machines, small (medium) casting machines, production casting machines, slitting and cutting machines, punching machines, screen printing machines, stackers, warm isostatic pressing machines, heat cutting machines, and other supporting equipment. We have become the leading supplier of manufacturing and research equipment, providing excellent solutions for manufacturing and scientific research. Our products are widely used in electronics, physics, environmental protection, new energy, energy storage materials, and other fields.

Dron Technology adheres to the core philosophy of "people-oriented" and the business philosophy of "active innovation," striving to build a high-end equipment brand in the industry and making every effort to contribute to production and scientific research development!